Laser Engravable Rubber & Polymer

Laser Engravable Rubber & Polymer

SKU:LR-LY

Couldn't load pickup availability

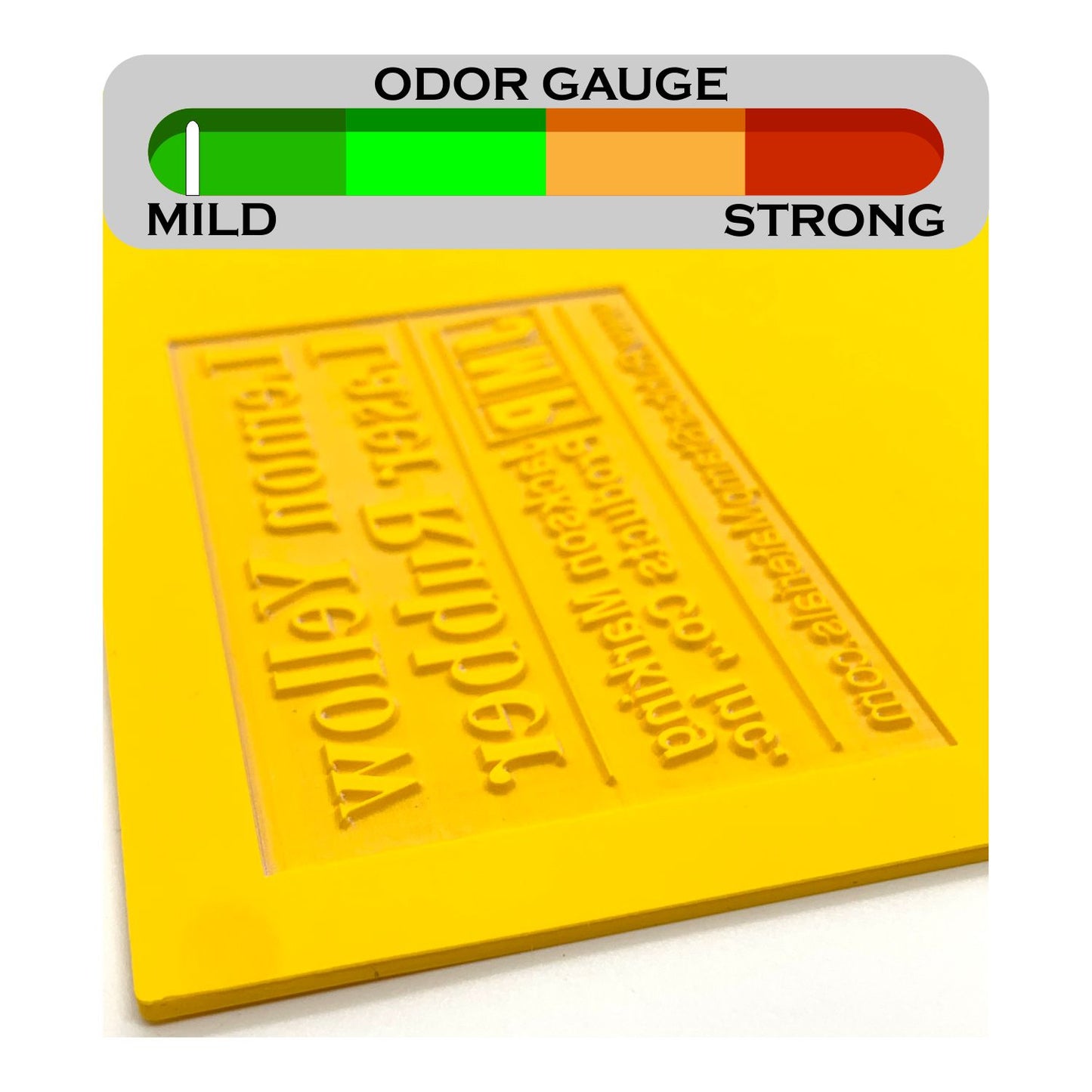

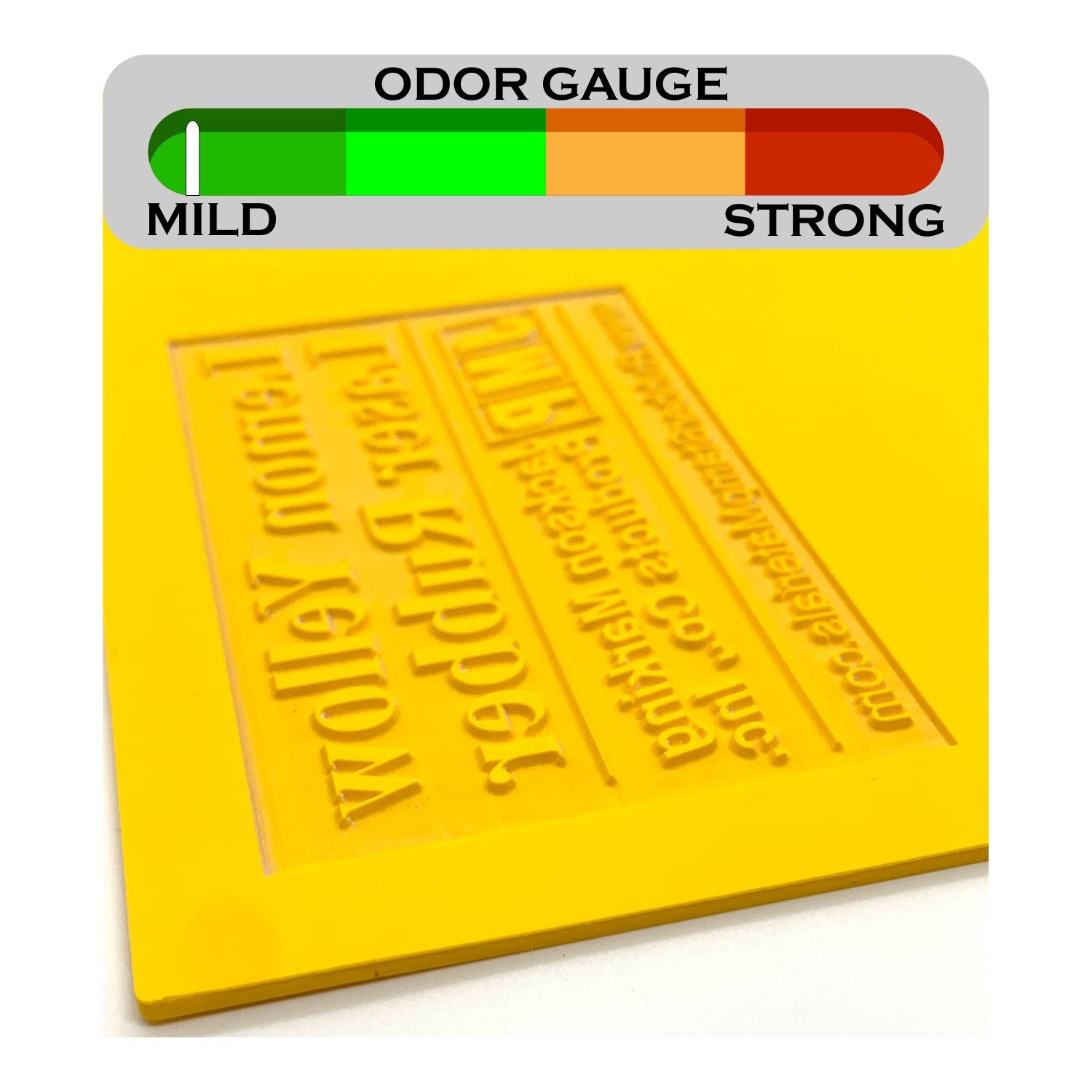

NEW!! Lemon Yellow Laser Rubber emits a pleasant lemon aroma while engraving and in washout. Engraves easily and becomes a very durable stamp die. 8 1/4" x 11 3/4" (A4) sheets and is approx. .090" thick. Bright yellow color. Recommended for general stamping applications or self-inking stamps with regular stamp inks.

Our pre-vulcanized Premium Pink Laser Rubber is available in 8 1/2" x 11" sheets and is approx. .100" thick. Pinkish-red color. Burns cleanly leaving a white ash residue. Recommended for general stamping applications or self-inking stamps with regular stamp inks. In production it has an odor that may be offensive to some people.

Buna-N Synthetic Laser Rubber is a black material used to form stamp or printing dies that will be used with alcohol, acid or oil based inks. 8 1/2" x 11" sheet size. Approximately .100" thick. It is not necessary to use Buna-N Rubber for most stamp production -- only industrial use stamps require Buna-N. Engraves with a strong odor.

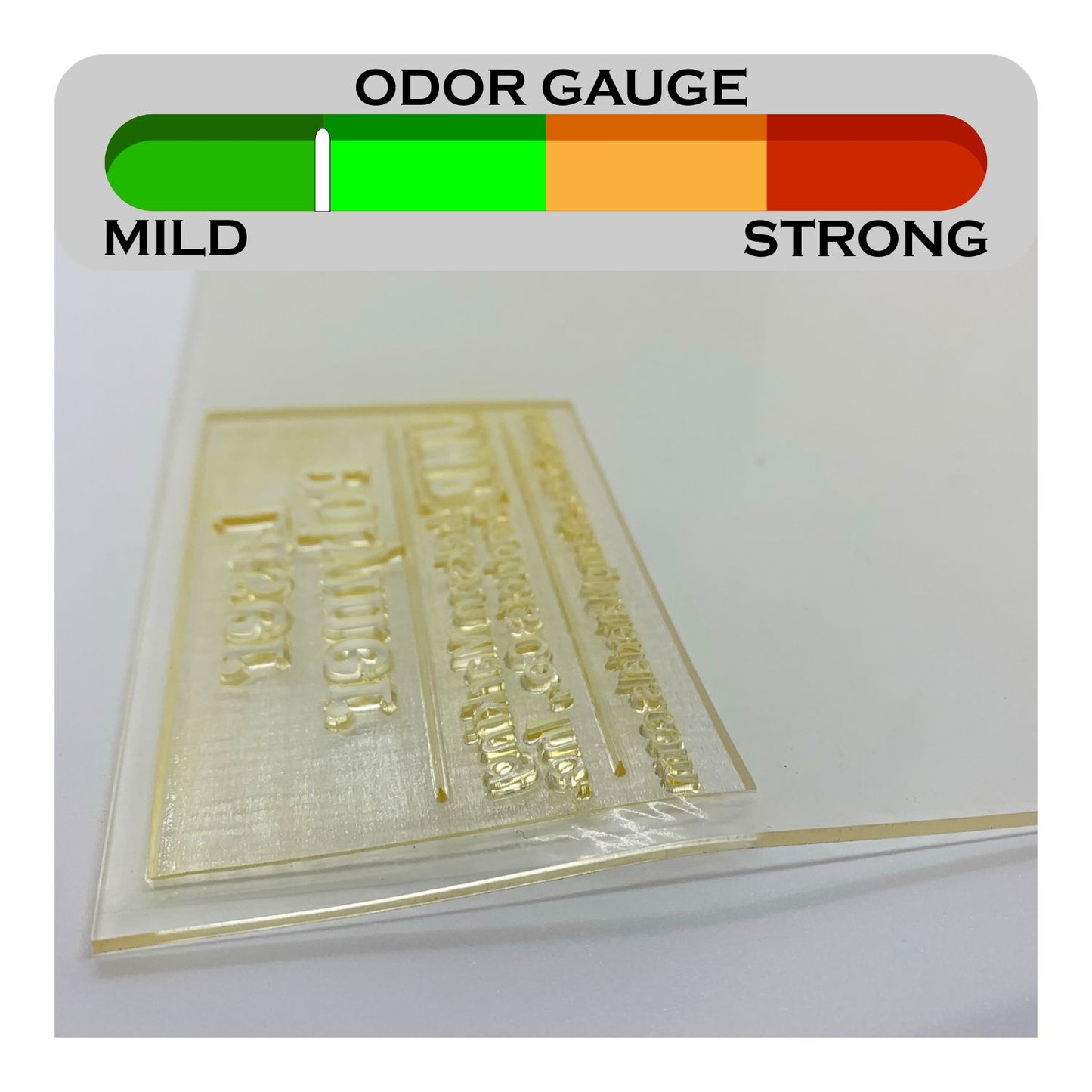

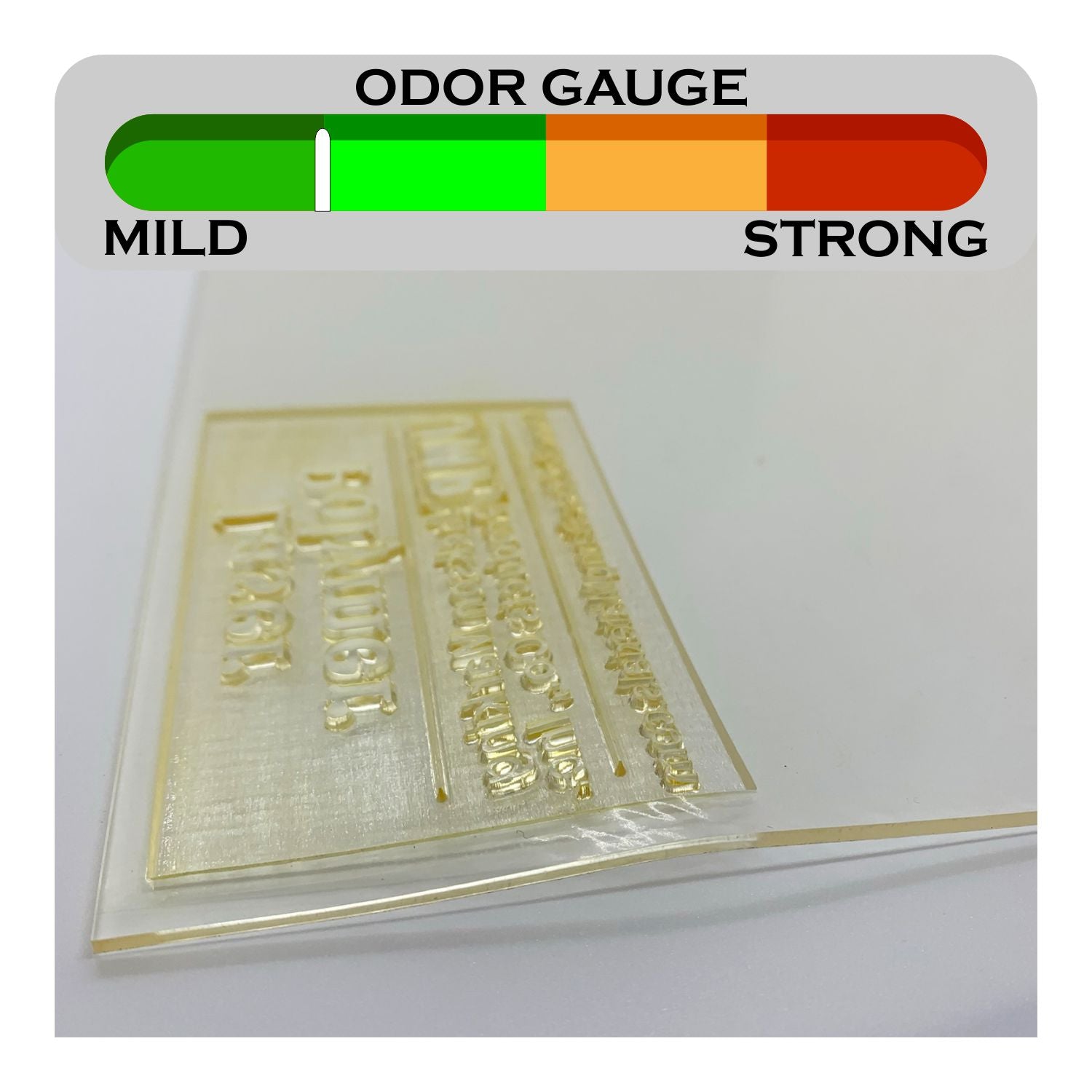

About Laser Polymer:

• Always engrave the side that has a thin plastic coating. Pull the thin plastic off before engraving.

• When vector cutting this material be sure to use a vented cutting table. Without a cutting table the polymer will melt.

• After engraving, immediately wash the material with detergent and water (if you wait, it will be more difficult to wash off). Then rinse and towel dry.

• If the plate is sticky after washing, you can apply a thin layer of mica powder.

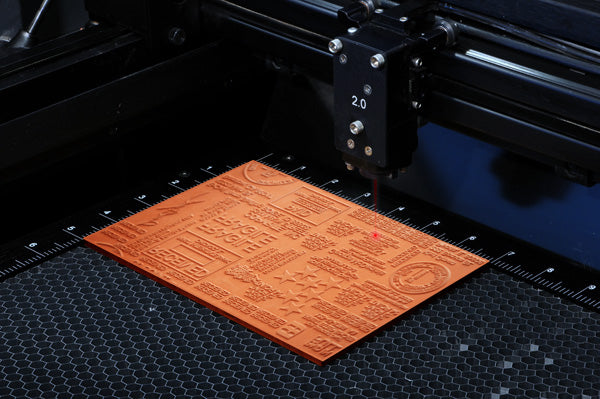

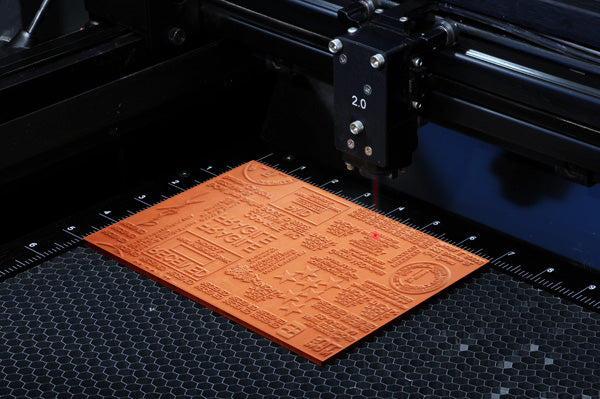

These settings are a good starting point as you begin test engraving our materials. If unsure about how to implement any of these recommendations or precautions contact your equipment manufacturer for assistance.

• Use your laser’s software settings for “stamp” mode or “3D effects” mode. Use your machine’s air assist mode while engraving.

• HIGH power, SLOW speed. When engraving, 80% to 100% power is standard and head velocity can be anywhere from 2% to 20% depending on the wattage of your laser machine. When vector cutting, 60% to 100% power is standard and head velocity ranges from 1% to 5%. A range of 500PPI to 1000PPI is standard for both engraving and vector cutting.

• If the material has a rough and a smooth side, always engrave the smooth side.

• After engraving wash the material with detergent and water using a soft brush, then rinse and towel dry.

Always observe the following precautions:

• Laser engraving or cutting rubber or polymer can possibly ignite the material. Never leave the laser system running unattended for any reason.

• When vector cutting these materials be sure to use a vented cutting table. Without a cutting table the likelihood of flame increases.

• Laser engraving or cutting rubber or polymer can produce foul odors. You may need to particulate filter or odor filter your exhaust depending on your environment, installation location and local air quality control regulations.

• Laser engraving or cutting rubber or polymer can produce abrasive dust and smoke. You will need to keep the optics clear and clean your laser more frequently to reduce wear and tear.

Share