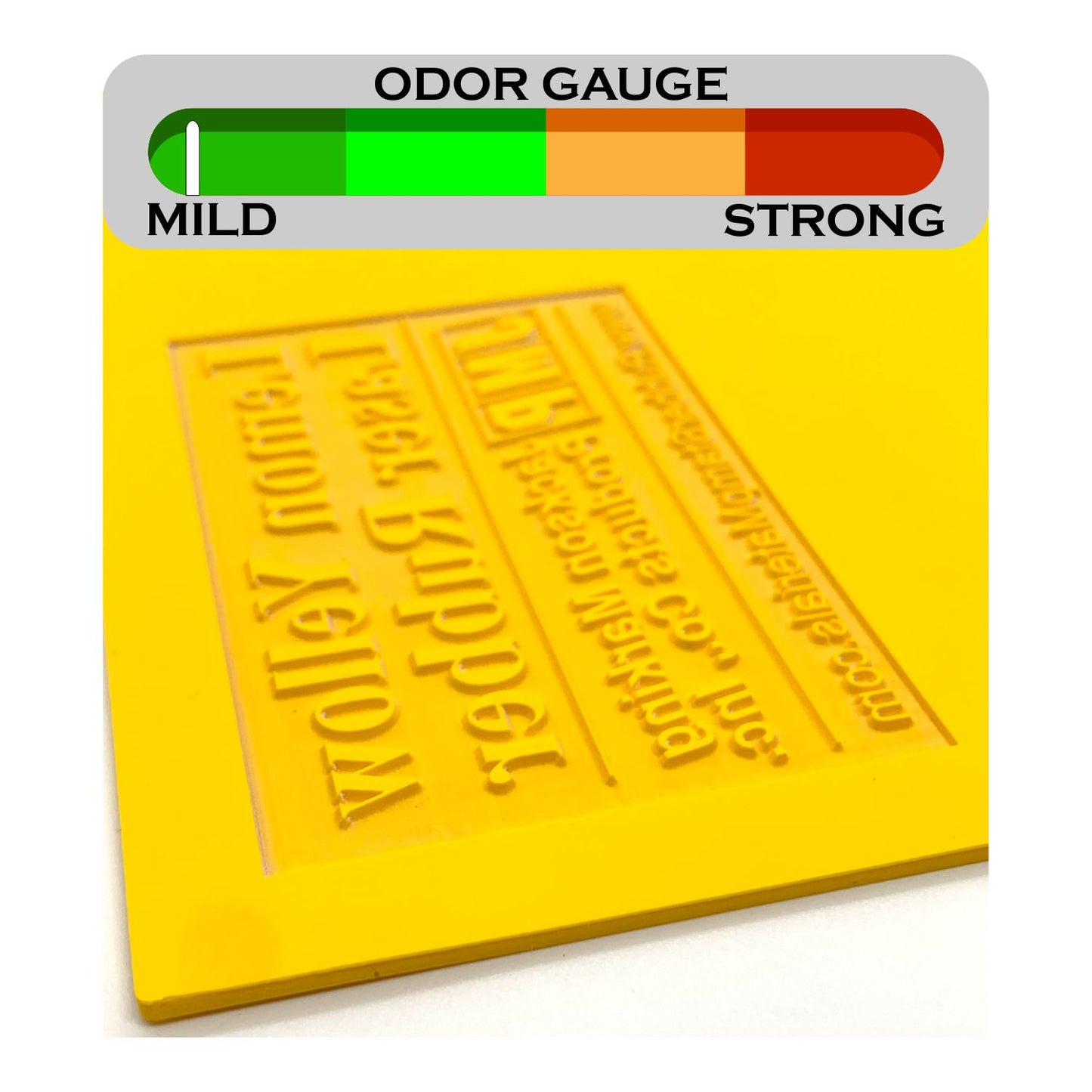

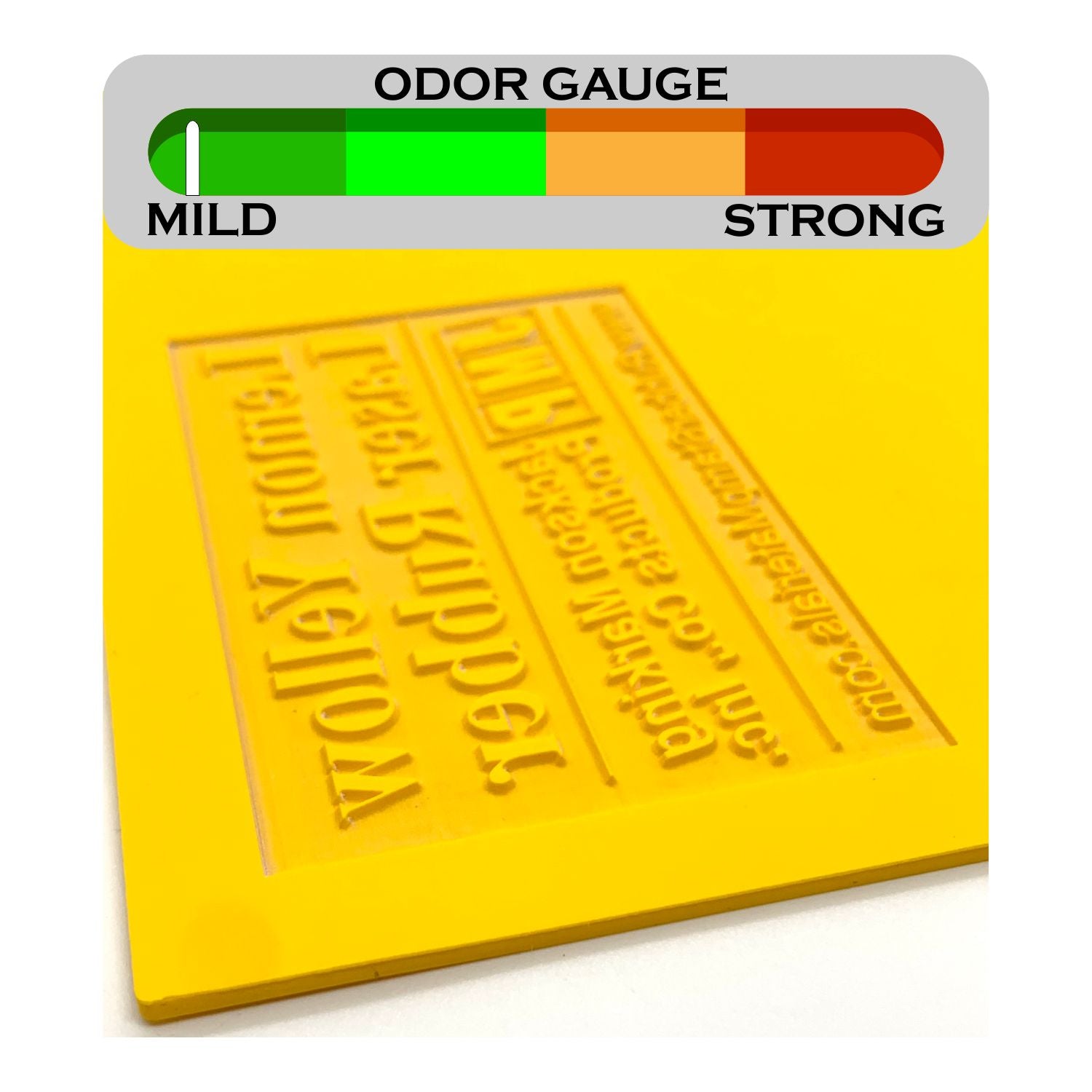

Lemon Yellow Laser Rubber

Lemon Yellow Laser Rubber

SKU:LR-LY

Couldn't load pickup availability

These settings are a good starting point as you begin test engraving our materials. If unsure about how to implement any of these recommendations or precautions contact your equipment manufacturer for assistance.

• Use your laser’s software settings for “stamp” mode or “3D effects” mode. Use your machine’s air assist mode while engraving.

• HIGH power, SLOW speed. When engraving, 80% to 100% power is standard and head velocity can be anywhere from 2% to 20% depending on the wattage of your laser machine. When vector cutting, 60% to 100% power is standard and head velocity ranges from 1% to 5%. A range of 500PPI to 1000PPI is standard for both engraving and vector cutting.

• If the material has a rough and a smooth side, always engrave the smooth side.

• After engraving wash the material with detergent and water using a soft brush, then rinse and towel dry.

Always observe the following precautions:

• Laser engraving or cutting rubber or polymer can possibly ignite the material. Never leave the laser system running unattended for any reason.

• When vector cutting these materials be sure to use a vented cutting table. Without a cutting table the likelihood of flame increases.

• Laser engraving or cutting rubber or polymer can produce foul odors. You may need to particulate filter or odor filter your exhaust depending on your environment, installation location and local air quality control regulations.

• Laser engraving or cutting rubber or polymer can produce abrasive dust and smoke. You will need to keep the optics clear and clean your laser more frequently to reduce wear and tear.

Share